ALANN: Using Image Recognition to Aid Quantum Device Development

Novel computing techniques have the potential to bring in rapid advances in a wide range of industries. Among these techniques is quantum computing. Based on a quantum bit (qubit), bringing together a number of them allows for increased computing power, similar to bits in a traditional computer. Currently, quantum devices are made of a handful of qubits, whereas for truly transformative advances, large numbers of qubits will be needed.

The Atomic Lithography Automation using Neural Networks (ALANN) project is a collaboration between Nanolayers and other small companies and research institutes in Canada and the UK. The aim of this project is to rapidly increase the number of qubits that can be fabricated. The focus is on fabricating qubits in silicon, building upon an unparalleled wealth of technology that has been built since the 1950s and allows for seamless integration into production.

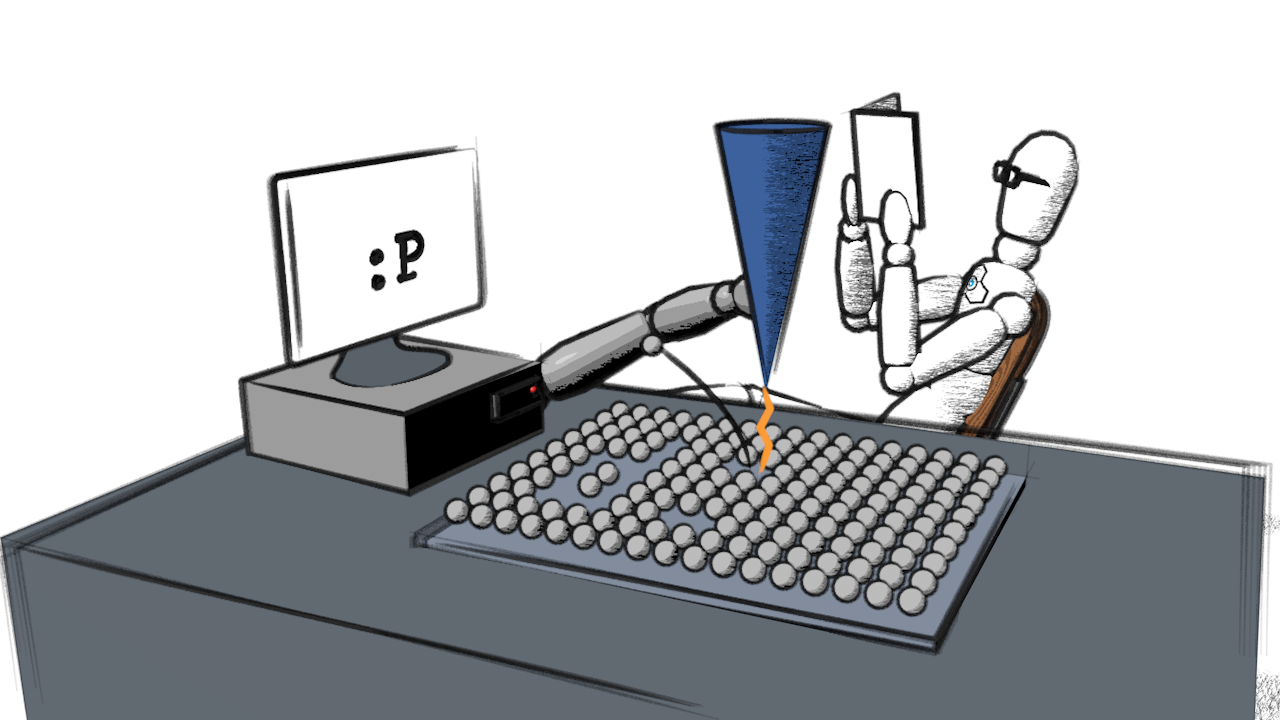

Fabricating qubits involves precise manipulation of impurity atoms at an atomic level using a scanning tunneling microscope. This process is manual and rather laborious. Therefore, to scale up the process and manipulate many more atoms, advanced machine controls and data processing tools. Using Nanolayers' proprietary machine learning tools, the tunneling microscope will be trained to manipulate and fabricate qubits on its own. Such a methodology allows our partners to manipulate large collections of atoms and create devices with large numbers of qubits. This work will eventually lead to a silicon based quantum computer.

Check out the Innovate UK announcement!